-

Hunting Weapons

-

Regulated weapons

-

Sporting & Leisure Weapons

-

Alarming & Self-Defense Weapons

-

Optics, Lamps and Electronics

- Optics, Lamps and Electronics

- Cameras and video surveillance

- red dot scope

- hunting scope

- shooting Glasses and tactical

- Glasses and red dot compressed air

- Rangefinders and collimators

- Assemblies, rails and adapters

- Binoculars, telescopes, observations glasses

- Camera and night vision

- Talkie Walkies & radios

- Flashlights & torches

- Laser and tactics lampes

- Metal detector

- Piles & batteries

-

Hunting Defense Ammunition

- Hunting Defense Ammunition

- hunts cartridge

- central percussion Ammunitions

- Shooting & regulated ammunition

- Reloading equipment

- Reloading consumables

- Black powder ammunitions

- 22 lr, 17 HMR, 6mm & 9mm Flobert Ammunitions

- Blank cartridges, gaz cartridges and rubber bullets

- Smoke and flare

- Lead and ammunitions for airguns

- Storage boxes for bullets

-

Accessories & Bags

- Accessories & Bags

- hunting horns and whistles

- Bird calls, rings

- Town and country planning

- fox Traps and harmful, hide and camouflage

- maintenance products

- Set of cleanings and brushes

- Plates of coats, buscs and skullcap

- Gongs and targets

- Aiming, handlebar and grenadieres

- bipods,tripods and pirsch sticks

- Walking stick and seats

- Coffres & verrous

- Suitcases, rifles cases and backpacks

- Sholder bags, cartridge belts and straps

- Car equipement

- Hearing protection, masks & eyewear

-

Hunting Outfits & Acc. Dogs

-

Archery, Cutlery & Gifts

- Archery, Cutlery & Gifts

- Crossbows and tiles

- Bows and arrows

- Arrows, points and feathers

- Targeting, archery accessories

- slingshots and blowpipes

- Straight hunting knives

- Tactical straight knives

- Survival knives

- Folding knives

- Swords and sabres

- Machette & hatchet

- Survival and to outdoor

- Children's games and cuddly toys

- Portes fusils, écussons à trophées.

- Cadeaux

-

Airsoft & Paintball

- Airsoft & Paintball

- Airsoft - secondary weapon

- Airsoft - primary weapon

- Airsoft - Batterie & fusibles

- Airsoft - Grenades and mines replicas

- Airsoft - Balls, Gas & Co2

- Airsoft - Airsoft accessories

- Airsoft - Tactical equipements

- Airsoft - Professional equipement

- Airsoft - Ground equipment

- Airsoft - Clothes and protections

- Airsoft - Bags, carrying bags and luggages

- Airsoft - Spare parts & upgrades

- Paintball - Guns and rifles

- Paintball - Loaders & tubes

- Paintball - Ammunition

- Paintball - Compressed air and Co2

- Paintball - throwers accessories

- Paintball - Masques and helmet

- Paintball - Harnais/vestes tactiques

- Paintball - Games outfit

- Paintball - Cleaning and maintenance

- Paintball - Ground accessories

- Swap-Archery

Lead-free cartridges!

The choice of material for the manufacture of hunting cartridge “ leads ” requires taking into account several factors: the spherical shape of the balls, the density of the material, and its elasticity for energy transfer. Furthermore, it is crucial that the material is easily accessible for industrial production while remaining economically affordable for end users.

Small point on the regulations:

The OFB has already instructed its agents to fine those who violate the regulations.

Here are the new regulations relating to hunting in wetlands:

- The use of lead shot is prohibited in wet areas and within a radius of 100 meters around them.

- If you transport cartridges containing lead shot into these areas, you are presumed to have violated the rule, and it will be your responsibility to demonstrate that you did not use them.

Reminder : The definitions of wetlands remain constant and unchanged, which means that the notion of temporary puddle which had been mentioned is no longer taken into consideration.

Several types of materials:

1. Steel

Due to their virtually indestructible nature, steel balls retain their spherical shape, while providing excellent sheaf density.

However, due to their lower density (31% less than lead), a higher initial velocity is required, and it is recommended to increase the caliber of the balls by two sizes compared to those of lead to maintain the same final kinetic energy. To ensure optimal performance at further distances, it is essential to adjust both payload and speed.

One of the main advantages of steel balls is their excellent penetration capacity (5-10% increase). The resulting spray is more uniform, denser, but also shorter (which can be reduced by up to 50% compared to lead balls). Additionally, the cost remains affordable, which is a crucial advantage for shooters and hunters.

2. Bismuth & Alloys

Bismuth or alloys (Bismuth, aluminum, tin & zinc) are heavy metals, displaying a density very similar to that of steel, and they demonstrate performances comparable to the latter. The main characteristic of bismuth lies in its flexibility, which allows it to be used by all types of cannons, including those intended for steel balls. This flexibility allows the loading of bismuth cartridges with a traditional wad.

The high density of bismuth as well as its deformation properties upon impact result in significant energy transfer. By opting for bismuth, it is possible to maintain the same number of beads as before while enjoying these advantages.

Substitute alloys are made of lead-free metals that are non-toxic to the environment. In addition, they have almost the same ballistic characteristics as lead in terms of hardness, lethality and penetration.

Copper: some cartridges are loaded with copper shot which also forms an excellent alternative to lead and other lead substitutes. Copper has an intermediate hardness between steel and lead and an interesting density: Copper: 8.9 kg/l, Steel: 8.0 Kg/l, Bismuth: 9.8 Kg/l and Lead 11.3 Kg /L

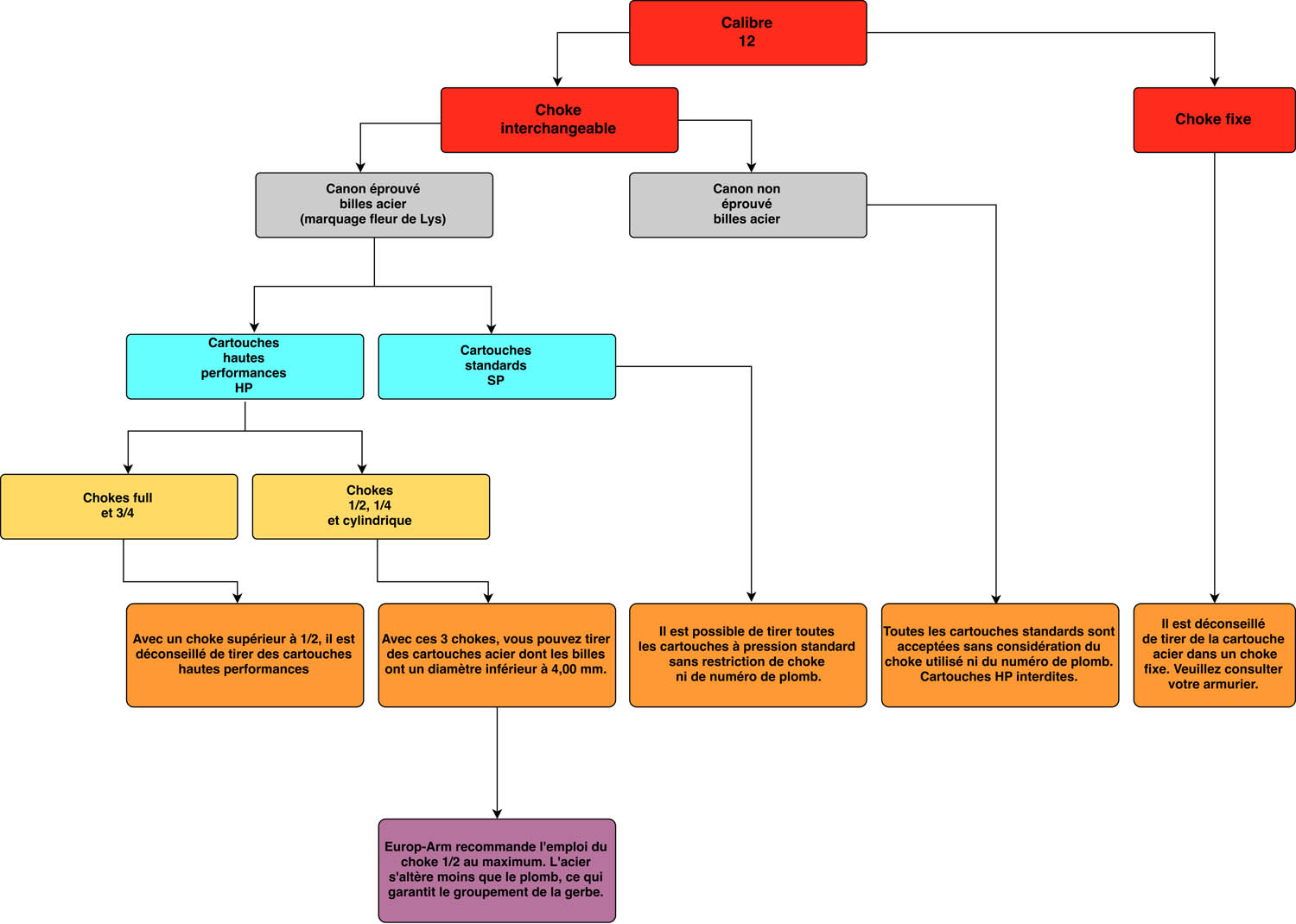

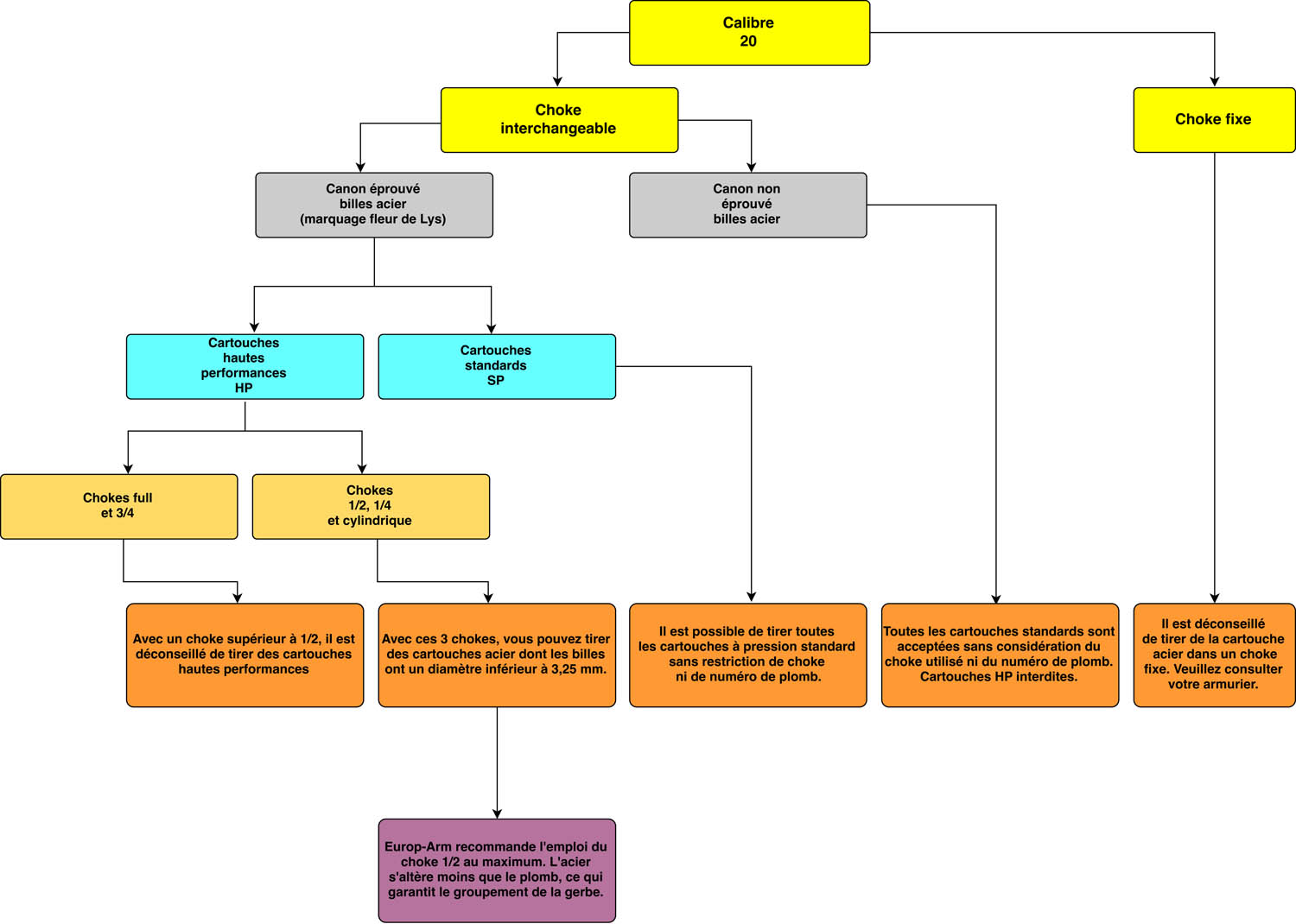

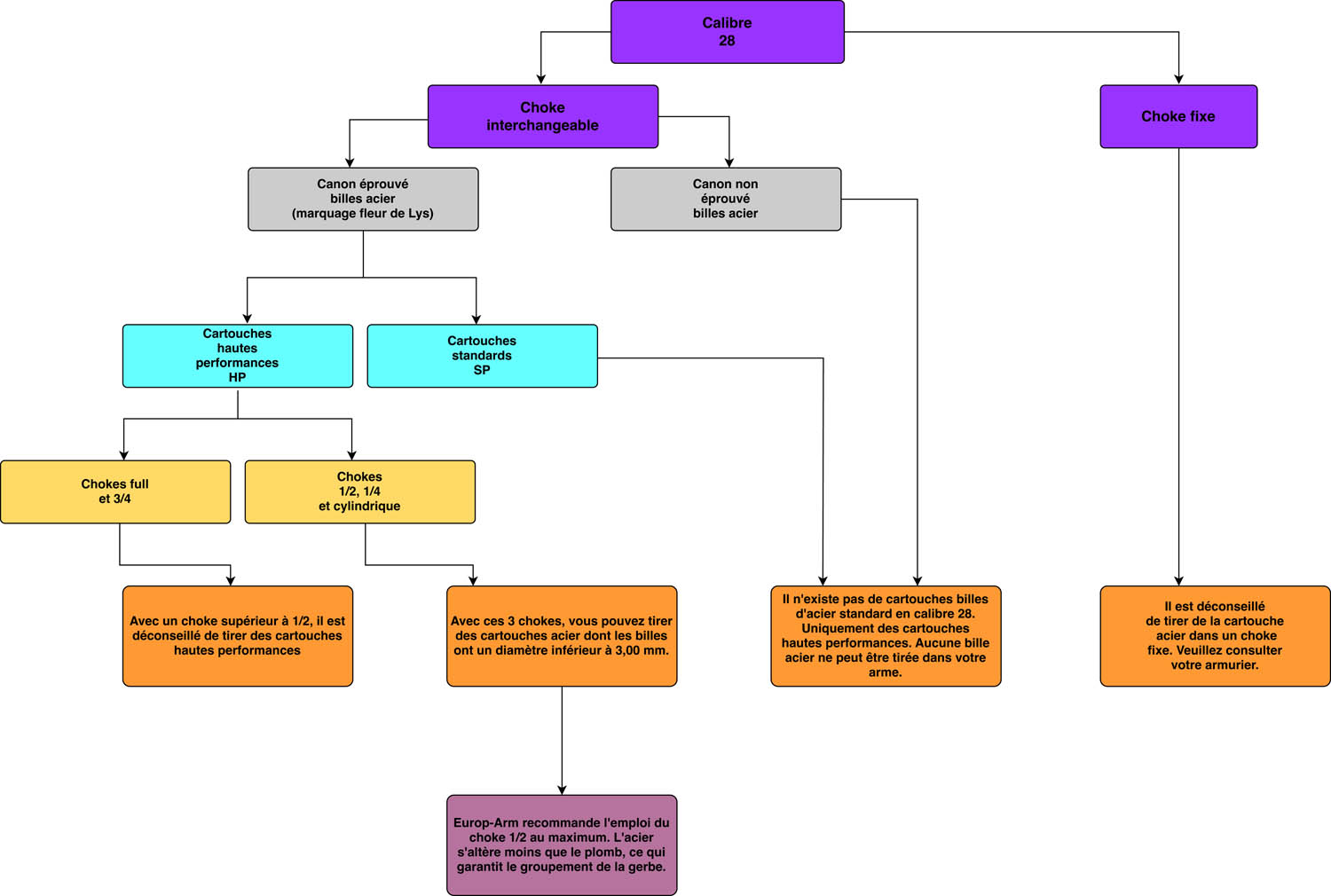

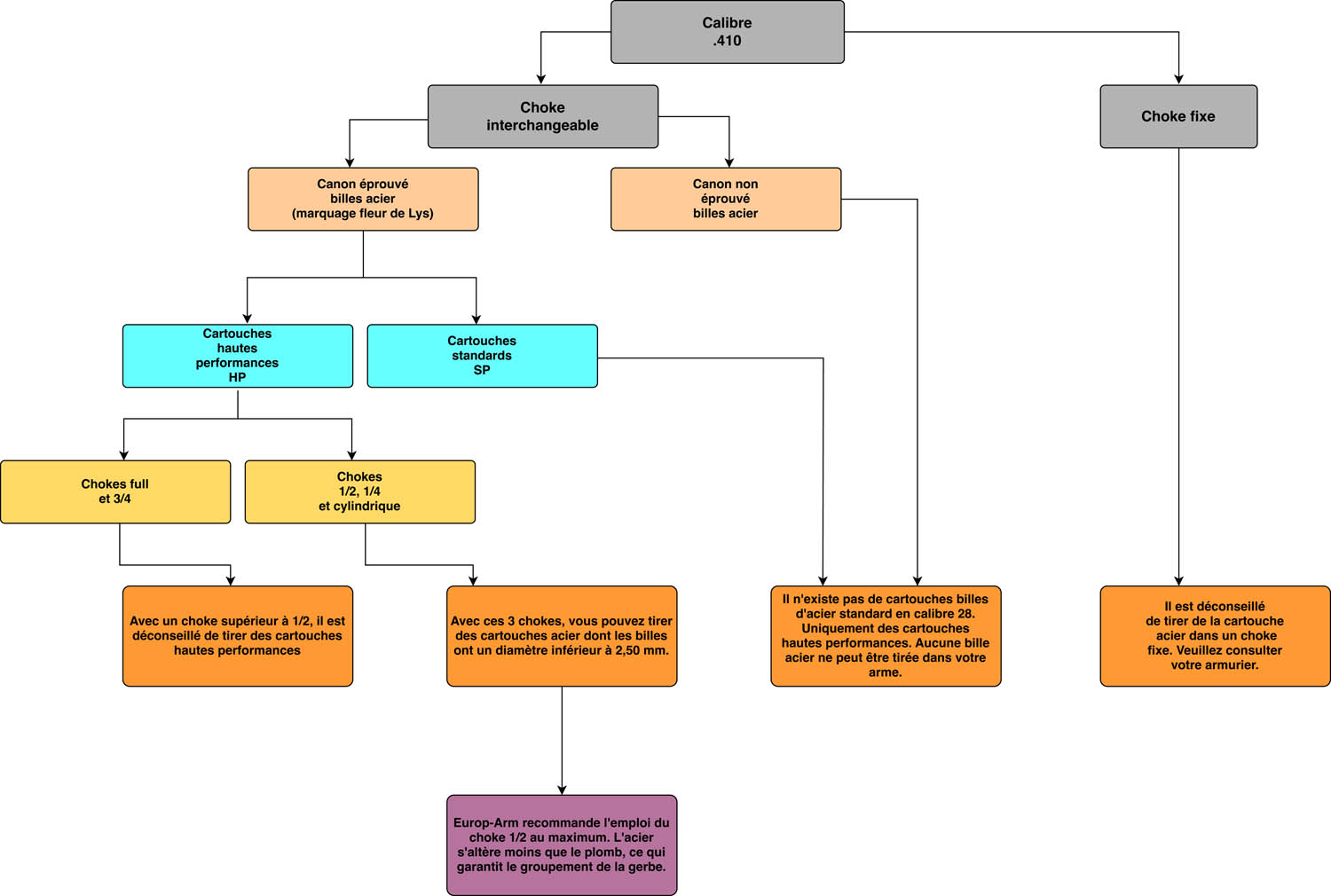

CIP rules

According to the guidelines of the CIP (Permanent International Commission for the Testing of Portable Firearms), there are two categories of approval for lead-free steel cartridges:

- the category “Ordinary Pressure” or in English “Standard Pressure” which will generally be abbreviated to SP

- the “High Performance” category or in English “High Performance which will generally be abbreviated to HP

Steel cartridges in the “Ordinary Pressure” category are compatible with all proven rifles up to a pressure of 930 bars. If your weapon is accompanied by a form from the St-Etienne test bench, you will find the test pressure of your rifle there.

As for the steel cartridges in the “High Performance” category, they are specifically designed for rifles tested for steel balls, with a pressure of 1320 bars and bearing the CIP fleur-de-lis hallmark.

It is strongly recommended to use ½ or smaller chokes (1/2, ¼, Cylindrical) with cartridges in the “High Performance” category.

In both cases, it is imperative that the type of cartridge approval is clearly mentioned on the packaging and the cartridge tube.

1st case: SP (Standard/Ordinary Pressure)

- Max cartridge pressure: 830 bar (Maximum pressure varies depending on caliber)

- Maximum speed: 425m/s at 2.5m

- Diameter for steel balls max. : < 3.25mm

- Authorized removable chokes: All

- Authorized weapons: Removable chokes exclusively Tested at 930 bars min

2nd case: HP (High performance)

- Maximum cartridge pressure: 1050 bar (Maximum pressure varies depending on caliber)

- Maximum speed: 430m/s at 2.5m

- Diameter for balls max. : None

- Authorized removable chokes: Ball > 4mm

- Recommended removable chokes: ½ max for all ball sizes

- Authorized weapons: Removable chokes exclusively Steel balls tested at 1320 bars Fleur de Lys marking

Safety: a key point!

Safety is always a crucial point when using a weapon. We will only talk here about the specific safety related to the use of lead substitute ammunition in smooth-bore shotguns. Safety concerns the resistance of the weapon, but also the specific behavior of the magazine linked to the use of ammunition with steel balls, bismuth or other lead-free alloy.

Regardless of the material used, it is imperative to always strictly follow basic safety rules when shooting cartridges.

It is essential to understand the meaning of the proofhouse mark on your barrels, as well as which cartridges are safe to use. In addition, it is crucial to distinguish between “Ordinary Pressure” and “High Performance” steel cartridges, and those that can be used safely.

The possibility of ricochets should always be kept in mind, particularly in aquatic environments, around branches or within dense vegetation. Never fire a shot unless you are sure of your target and can see it clearly. It is important to avoid mixing cartridges of different calibers.

When using cartridges with a wad made from an alternative material or a so-called “degradable” material, it is essential to guarantee constant protection of the barrel and to avoid any damage to the internal walls of the cartridges. cannons caused by the balls.

Hunting: adapted behavior

Since steel has a lower density, the residual velocity will also be less, thus requiring a necessary adjustment to your aim (lead). Steel cartridges provide optimal performance at distances ranging from 25 to 30 yards.

The steel projectiles are unalterable, and the use of a choke up to ½ maximum guarantees optimal and precise dispersion. When opting for new lead-free cartridges, it is recommended to practice beforehand on a shooting range, in order to better understand the behavior of projectiles and dispersion at different distances.

Comparatively, bismuth has a higher density than steel, which allows shots at greater distances, up to 55 meters (60 yards). Bismuth projectiles, unlike steel ones, have greater deformability, which means you can continue to use your usual chokes.

Alloy projectiles have an intermediate behavior between steel and Bismuth which is very close to the behavior of lead. It is also advisable to carry out tests on the range to become fully aware of the behavior of the ammunition in action.

Cartridges and specifications for each caliber

- Cal. 12

- Cal. 20

- Cal. 28

- Cal. 410

Lexicon

- HP stands for High Performance: Cartridges classified as high performance must be used exclusively in steel shot guns at a pressure of 1320 bars, and they generate a maximum pressure of 1050 bars.

- SP stands for Standard Pressure: Standard pressure cartridges are designed to be fired in rifles tested at 1040 bars and generate a pressure below 830 bars. The balls contained in these cartridges have a maximum diameter of 3.00 mm (number 5). The inscription “Standard Pressure” is present on the socket.

- Fleur de Lys: The Fleur de Lys symbol indicates that the rifle is approved for steel shot. All hunting or sporting rifles bearing the fleur-de-lis hallmark can use “High Performance” cartridges containing steel balls.

This hallmark is affixed to the barrel of the rifles by a certified proofing bench. On recent weapons, the new hallmark also includes the CIP marking above the fleur-de-lys.

Pictures are not contractual. Photos of product may be different with the final products.

Texts, brands and characteristics are not contractual as they are liable to change depending on arrivals.

- Winchester: Choose your cartridges carefully depending on the game.

- Hunting “silencers”: Why approve them?

- Hera Arms Company - Presentation and product ranges

- Black Fire Company - Presentation and product ranges

- Lead-free cartridges!

- YILDIZ company - Presentation and product ranges

- Chiappa FireArms Company - Presentation and product ranges

- Renato Baldi Company - Presentation and product ranges

- Sierra: The different projectiles and their characteristics.

- Norma: the different warheads and their characteristics

- Shooting glossary

- The different types of warheads at Winchester: What does it correspond to?

- Weapons: definitions in the legal sense

- Red dot sights: How to choose?

- Regulations on chargers by the SCAE

- Archery: choose your arrow spin

- Company Davide Pedersoli - Presentation and product ranges

- Choose your thermal night vision

- SIA holder space user guide

- The different hunting modes

- The disciplines of sport shooting

- EUROP-ARM IS RECRUITING!

- 5 tools for a good natural referencing of your website

- LE SIA : RGA et LPN - Les grandes étapes

- Paintball Vocabulary

- Legal information and regulations

- Comment les internautes ont trouvé notre site jusqu'à maintenant ?

- Ici, Europ-Arm répond à vos questions !

- Articles web - On parle de nous !

- Charte Europ-arm / Sport-attitude / Armsco de protection des données personnelles dans le cadre de la RGPD

- Europ-Arm helps to choose the right shotgun

- Le conseil de l'expert ! Comment bien choisir sa paire de jumelles ?

- Europ-Arm website support

- Catégories des armes

- Hunting and shooting whosaler

- Airsoft vocabulary

- Who are we ?